- Home Page

- Company Profile

-

Our Products

- Planter

- 11 Nest Planter

- 10 Nest Planter

- Dutch Tray Planter

- 12 Waves Planter

- 12 Conica Planter

- 18 Conica Planter

- 12 Cubix Planter

- 36 Conica Planter

- 30 Capsica Planter

- 30 Stonex Planter

- Quad Epic Planter

- Quad Turbo Planter

- Greek Tray Planter

- 24 Conica Planter

- 30 Conica Planter

- Sleek Planter

- 11 Stylish Plastic Planter

- 24 Cubix Planter

- 18 Cubix Planter

- 19 Cubix Planter

- 25 Cubix Planter

- 30 Timberlux Planter

- Stripes Planter

- 12 Fluted Planter

- 24 Fluted Planter

- Dots Planter

- 36 Fluted Planter

- Square Planter Tray

- Stripes Planter Plastic

- Polka Dot Planter

- Plastic Dustbins

- 20 Litre Plastic Dustbin

- 10 Litre Plastic Dustbin

- 12 Litre Plastic Dustbin

- 100 Ltr Plastic Dustbin

- 60 Litre Blow Mould Dustbin

- 80 Litre Blow Mould Dustbin

- 40 Litre Wheel Cart Bins

- Hdpe Open Top Drum 60 Ltr

- Plastic Composite Dustbin

- 100 Ltr Blow Mould Dustbin

- 100 Liter Twin Plastic Dustbin With Stand

- 80 Ltr Plastic Dustbin

- Plastic 30 LTR SWING DUSTBIN

- Household Swing Dustbin 60 Ltr

- 15 Litre Plastic Dustbin

- 40 Liter Plastic Square Dustbin

- 200 Litre Plastic Dustbins

- 80 Litre Dome Shape Plastic Dustbin

- 100 Litre Dome Shape Plastic Dustbins

- HDPE Open Top Drums

- 25 Litre HDPE Open Top Drum

- 35 Litre HDPE Open Top Drum

- 200 Litre HDPE Open Top Drum

- 30 Litre HDPE Open Top Drum

- 40 Litre HDPE Open Top Drum

- 90 Litre HDPE Open Top Drum

- 50 Litre HDPE Open Top Drum

- 50 Litre HDPE Narrow Mouth Drum

- 200 Litre Open Top Drum

- 75 Ltr HDPE Open Top Drum

- 65 Litre HDPE Open Top Drum

- 65 Litre HDPE Open Top Drum

- Plastic Campus Milk Cans

- Campus Plywood

- Water Resistant Campus Plywood

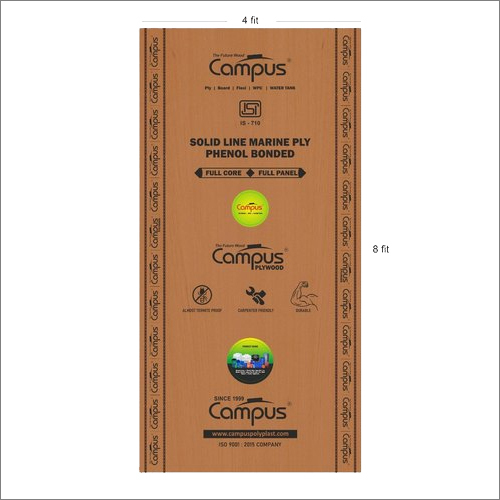

- Campus Marine Plywood

- Natrual Campus Solid Line Plywood

- Campus Forest WPC/PVC Sheet

- Pine Frame Plywood

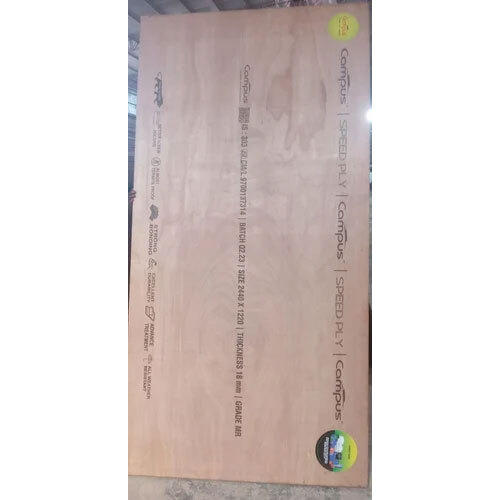

- Campus Speed Ply

- Campus Export Quality Water Proof Plywood

- Stuttering Plywood

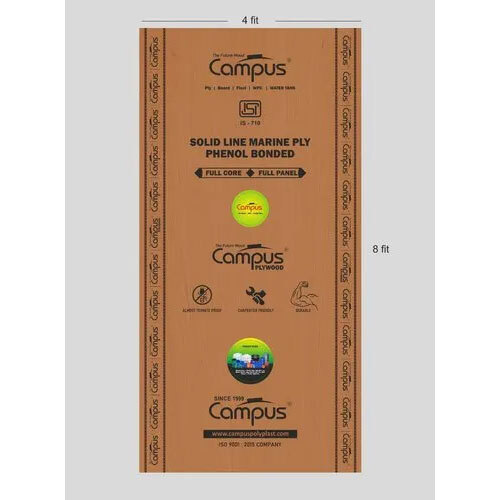

- Campus Solid Line Plywood

- Campus Export Quality Plywood

- Campus Solid Line Marine Plywood

- Campus Veneer Ply

- Campus Export Quality WaterProof Plywood

- Campus Plywood

- Campus Flat-X

- 34 KG Shuttering Plywood Sheet

- 30 KG Shuttering Plywood

- Agriculture Spray Tank

- Rotational LLDPE Water Storage Tanks

- Plastic Rhino Milk Cans

- HDPE Jerry Cans

- Wooden Door Frame

- WPC DOOR FRAME 3x2

- WPC DOOR FRAME SOLID 5x2.5

- WPC DOOR FRAME 6X2.5

- Natrual WPC DOOR FRAME 6X2.5

- Brown Wpc Door Frame Solid 5X2.5, Size 5X2.5

- WPC Door Frame 6X2.5

- WPC Door Frame 3x2

- Brown Matte Finish WPC Door Frame (6X2.5) - High Density

- 18 mm Campus Plywood Export Quality, Nailed Box

- WPC Door Frame 6X2.5

- Swing Dustbin

- Plastic Portable Toilet

- WPC PVC Sheets

- Plastic Can

- Floating Jetty

- Plastic Household Items

- Toilet Seat

- Plastic Invalid Commod Seat

- Plastic Milk Cans

- Floating Dock

- Loft Tank

- Planter

- Contact Us

Campus Marine Plywood

70 INR/Square Foot

Product Details:

- Usage Indoor and Outdoor Construction

- Surface Finish Uniform, sanded both sides

- Formaldehyde Emission Standards E1 Standard

- Feature Waterproof, Borer Proof, High Strength, Termite Resistant

- Grade MR & BWP Grades Available (IS 710)

- Back Smooth hardwood veneer finish

- Face Smooth, sanded hardwood veneer finish

- Click to View more

X

Campus Marine Plywood Price And Quantity

- 70 INR/Square Foot

- 100 , , Square Foot

- Excellent under both dry and wet conditions

- Eco-friendly manufacturing process

- Shipbuilding, Bathrooms, Kitchens, Partitions, Furniture, Roofing

- High

- Conforms to IS:710

- Hot Pressed

- Available with film facing or plain

- All edges sealed with waterproof paint

- Easy to cut, nail, and screw

Campus Marine Plywood Product Specifications

- Low

- Less than 15%

- Hardwood Veneer

- Waterproof, Borer Proof, High Strength, Termite Resistant

- E1 Standard

- High load bearing capacity suitable for structural applications

- 6% - 14%

- Smooth hardwood veneer finish

- Marine Plywood

- MR & BWP Grades Available (IS 710)

- Phenol-Formaldehyde (PF) Resin

- Smooth, sanded hardwood veneer finish

- 8*4

- Indoor and Outdoor Construction

- Boiling Water Proof (BWP) adhesive

- 0.3 mm thickness tolerance

- 700 Gram per cubic centimeter(g/cm3)

- Uniform, sanded both sides

- Gurjan/Poplar/Hardwood

- Available in various thicknesses (commonly 4mm to 25mm)

- Excellent under both dry and wet conditions

- Eco-friendly manufacturing process

- Shipbuilding, Bathrooms, Kitchens, Partitions, Furniture, Roofing

- High

- Conforms to IS:710

- Hot Pressed

- Available with film facing or plain

- All edges sealed with waterproof paint

- Easy to cut, nail, and screw

Campus Marine Plywood Trade Information

- 100 , , Square Foot Per Day

- 7 Days

Product Description

Specification

| Country of Origin | Made in India |

| Surface Finish | Matte |

| Wood Type | Hardwood |

| Glue Used | Phenol |

| Is It Sanded | Sanded |

| Is It Termite Resistant | Termite resistant |

| Thickness | 16MM |

| Brand | Campus |

| Is It Abrasion Proof | Abrasion proof |

| Is It Water Resistant | Water Resistant |

| Usage/Application | Furniture |

| Laminated | Yes |

| Size | 8*4 |

| I Deal In | New Only |

| Core Material | Poplar |

| Is It ISI Marked | ISI Marked |

| Color | Brown |

| Grade | First Class |

Superior Strength and Durability

Campus Marine Plywood offers excellent compressive strength under both dry and wet environments, making it a dependable choice for high-load applications such as shipbuilding, partitions, and roofing. The use of a Phenol-Formaldehyde resin and hardwood core ensures structural integrity and durability even in the harshest conditions.

Versatile and Eco-Friendly Applications

Engineered for flexibility, this plywood is suitable for both indoor and outdoor use, from bathrooms and kitchens to furniture and construction partitions. Its eco-friendly manufacturing process and E1 standard formaldehyde emissions ensure safety and environmental responsibility.

Precision Engineering for Lasting Performance

Every panel is meticulously manufactured to a 0.3 mm thickness tolerance and all edges are sealed with waterproof paint. A smooth, sanded finish on both faces provides an ideal surface for lamination, painting, or direct use, while the low water absorption rate preserves integrity over time.

FAQs of Campus Marine Plywood:

Q: How is Campus Marine Plywood protected from water damage during prolonged exposure?

A: Each panels edges are meticulously sealed with waterproof paint, and the plywood is bonded using Boiling Water Proof (BWP) Phenol-Formaldehyde resin, providing long-lasting resistance against moisture infiltration. Its low water absorption rate and conforming to IS:710 standards ensures lasting performance in humid and wet environments.Q: What makes Campus Marine Plywood suitable for structural applications and heavy load-bearing tasks?

A: The plywood is crafted from high-density hardwood veneers and core materials such as Gurjan, Poplar, and hardwood, resulting in a density of 700 g/cm3. Combined with its hot-pressed construction and superior compressive strength in dry and wet states, it delivers a high load-bearing capacity ideal for partitions, roofing, and heavy-duty furniture.Q: When should I choose Marine Plywood over regular plywood?

A: Marine Plywood is recommended whenever structures are exposed to moisture, humidity, or require high structural strength. Use it in shipbuilding, kitchens, bathrooms, roofing, and partitions where water resistance, durability, and long life are crucial compared to standard plywood.Q: Where can Campus Marine Plywood be applied?

A: It is designed for both indoor and outdoor settings, including shipbuilding, kitchens, bathrooms, partitions, roofing, and furniture. Its strong resistance to water, borers, and termites makes it appropriate for a variety of high-moisture and challenging environments.Q: What is the process for manufacturing Campus Marine Plywood?

A: The plywood undergoes a hot-pressing process using hardwood veneers and a Phenol-Formaldehyde (PF) adhesive, followed by edge sealing with waterproof paint. The panels are sanded on both sides for a smooth finish, and each batch adheres to IS:710 and E1 emission standards for quality and safety.Q: How easy is it to work with Campus Marine Plywood during construction?

A: This plywood is designed for excellent workability; it can be cut, nailed, and screwed with ease. Its high screw-holding capacity and tolerance control ensure precision in applications like furniture making, partitioning, and structural installations.Q: What benefits do the environmental compliance and E1 formaldehyde emissions offer to users?

A: An eco-friendly manufacturing process and conformance to E1 formaldehyde emission standards contribute to healthier indoor air quality and minimal environmental impact, making it a responsible choice for both residential and commercial projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email